Tuning a motion control system with ultra-precision controllers like ACS Motion Control or Elmo servo drives requires a systematic approach to ensure optimal performance. Dynamic tests are crucial for assessing system behavior under real-time motion conditions. Here’s an exhaustive list of standard procedures to follow during dynamic tests when tuning these systems:

1- Safety Checks and Setup:

- Verify Safety Limits: Confirm that hardware and software safety limits (e.g., soft and hard stops, torque limits) are correctly configured before testing.

- Emergency Stop Functionality: Ensure emergency stop buttons and limit switches are operational.

- Mechanical Inspection: Check for loose parts, mechanical play, or misalignments in the mechanical structure.

- Power Supply Check: Ensure the servo drives and controllers are receiving stable and correct voltage.

- Encoder Calibration/Alignment: Verify that encoders are properly aligned and calibrated to ensure accurate feedback.

2. Initial System Identification:

- Motor Data Verification: Cross-check motor specifications (e.g., torque constant, resistance, inductance) with system settings.

- Load Characterization: Measure or estimate the system’s load inertia, stiffness, and friction. Compare with motor and drive capability.

- Basic Signal Testing: Perform simple motion commands to verify that basic motion is possible without issues.

- Zeroing/Homing Procedures: Run homing sequences to establish a repeatable reference position for the system.

3. Basic Tuning Procedures:

- Control Loop Type Setup:

- Ensure correct control loop configuration (e.g., current/velocity/position loops).

- Manual PID Tuning:

- Start by tuning the current loop (if applicable), then proceed to the velocity and position loops.

- Use conservative gains to avoid instability in the initial tests.

- Proportional Gain (P): Adjust to minimize position/velocity error.

- Integral Gain (I): Fine-tune to remove steady-state errors.

- Derivative Gain (D): Use to dampen oscillations, but avoid excessive derivative action.

4. Dynamic Performance Tests:

- Open Loop Tests (if applicable):

- Run open-loop tests to ensure motor and drive functionality without feedback influence.

- Measure the response time and motor behavior (current, velocity).

- Step Response Tests:

- Perform step input tests to observe system response in terms of rise time, overshoot, and settling time.

- Capture position/velocity response during acceleration and deceleration.

- Bode Plot Analysis (Frequency Response Test):

- Generate Bode plots to identify resonance frequencies, bandwidth, and phase margins.

- Analyze system stability and adjust filters or PID gains based on frequency response data.

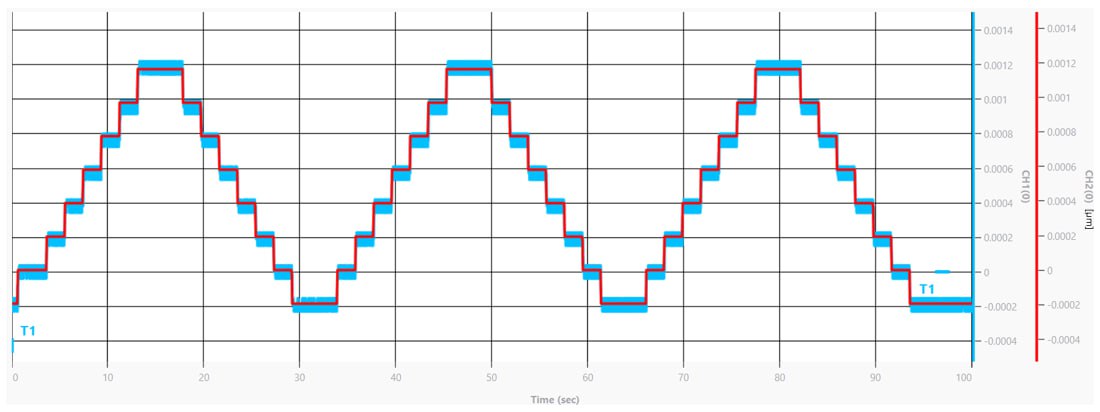

- Sinusoidal Sweep Testing:

- Apply sinusoidal reference signals at various frequencies and amplitudes to verify system tracking performance.

- Impulse/Disturbance Rejection Test:

- Apply external disturbances (torque or load) to evaluate how quickly the system compensates and stabilizes.

- Tune feedforward gains or implement filters if necessary.

5. Error Analysis and Feedforward Tuning:

- Position Error (Following Error):

- Record position following errors and determine if gains or system mechanics need adjustments.

- Fine-tune feedforward control to reduce following error during rapid acceleration/deceleration.

- Velocity Error:

- Check velocity loop performance and refine velocity feedforward terms.

- Evaluate velocity ripple and correct using filters or improved velocity loop tuning.

- Current Loop Error: (if applicable)

- Monitor motor current and compare with the command signal to ensure accurate current control.

6. Advanced Compensation Techniques:

- Notch Filter Tuning:

- Implement and tune notch filters to suppress mechanical resonance frequencies identified during dynamic tests.

- Low-Pass Filter Tuning:

- Use low-pass filters to eliminate high-frequency noise from feedback sensors.

- Advanced Gain Scheduling:

- Adjust control loop gains dynamically based on system state (position, velocity, load changes).

- Adaptive Control:

- If supported, enable and fine-tune adaptive control algorithms to adjust tuning parameters in real time.

- Friction and Cogging Compensation:

- Apply friction compensation and cogging torque compensation based on the system’s friction model.

7. Trajectory and Profile Testing:

- Standard Motion Profiles:

- Test standard motion profiles such as trapezoidal, S-curve, or custom velocity profiles.

- Evaluate system behavior during acceleration, constant velocity, and deceleration.

- Path Following and Contouring Accuracy:

- Test multi-axis coordinated motion (if applicable) for path following and contour accuracy.

- Check and correct for motion profile distortions caused by dynamics.

- High-Speed Testing:

- Evaluate system performance at high speeds, verifying motor and drive behavior under these conditions.

- Stop and Hold Testing:

- Perform abrupt stop tests to evaluate the system’s braking and hold performance (especially for vertical axes or critical applications).

8. Thermal and Electrical Considerations:

- Drive and Motor Temperature Monitoring:

- Monitor motor and servo drive temperatures during tests to avoid overheating.

- Validate that temperature protection mechanisms are functioning properly.

- Power Consumption and Current Monitoring:

- Measure power consumption, current spikes, and overall system power efficiency under dynamic conditions.

- Back EMF Compensation:

- Tune back EMF compensation (if supported) for better performance at high speeds or during dynamic braking.

9. Logging and Data Analysis:

- Capture Data Logs:

- Use the motion controller’s built-in logging tools to record detailed data (e.g., encoder feedback, current, position, and velocity errors) during tests.

- Log both transient (startup, stop) and steady-state conditions.

- Performance Metrics Analysis:

- Analyze performance metrics such as rise time, overshoot, damping, steady-state error, and position accuracy.

- Error and Alarm Analysis:

- Identify and troubleshoot any system errors or alarms generated during dynamic testing.

- Frequency and Time-Domain Data Analysis:

- Analyze system behavior both in the frequency domain (using tools like FFT) and time domain for a comprehensive understanding of performance.

10. System Finalization:

- Closed-Loop Stability Check:

- Perform a final system stability test under varying conditions (load, speed, temperature) to confirm reliable closed-loop behavior.

- Long-Term Drift Testing:

- Run prolonged tests to monitor for position or velocity drift over time.

- Operational Range Testing:

- Test the system under its full operational range (minimum to maximum load, velocity, and acceleration) to ensure robustness.

- Backup and Documentation:

- Save and backup all tuning parameters, including gains, filters, and any compensations applied.

- Document the tuning process, test results, and any special conditions observed.

11. Final Validation and Application Testing:

- Load Testing Under Real-World Conditions:

- Test the system with actual loads, speeds, and conditions relevant to its application.

- Repetition and Repeatability Testing:

- Perform repeated motion cycles to verify long-term repeatability and consistency in motion performance.

- Multi-Axis Synchronization (if applicable):

- Verify coordinated motion across multiple axes, ensuring that synchronization is within acceptable limits.

- Final Accuracy Validation:

- Test system accuracy by comparing actual versus commanded motion profiles over a series of movements.

Conclusion:

By following these standard procedures during dynamic tests, you ensure that ultra-precision motion systems are properly tuned for optimal performance, reliability, and safety. Each step helps identify issues, correct deviations, and fine-tune the system for high-performance applications.